The SMART 4.0® system is an integrated system designed for the control and supervision of industrial suction and filtering systems.

There is also the possibility of adopting a SMARTBOARD Ecotech GTS card, designed to be inserted inside the electrical control panel of the filtration system or in a dedicated box applied on the filter edge.

Its function is to detect the signals from the various sensors that can be applied to the system and which inform about its correct operation, as well as to control the pneumatic cleaning valves by means of air

tablet.

See what we can monitor

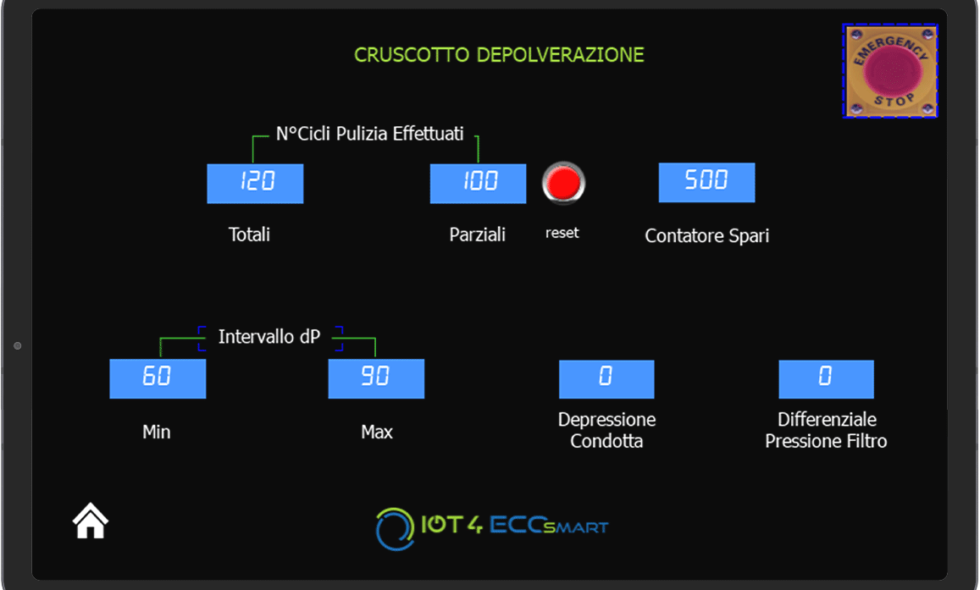

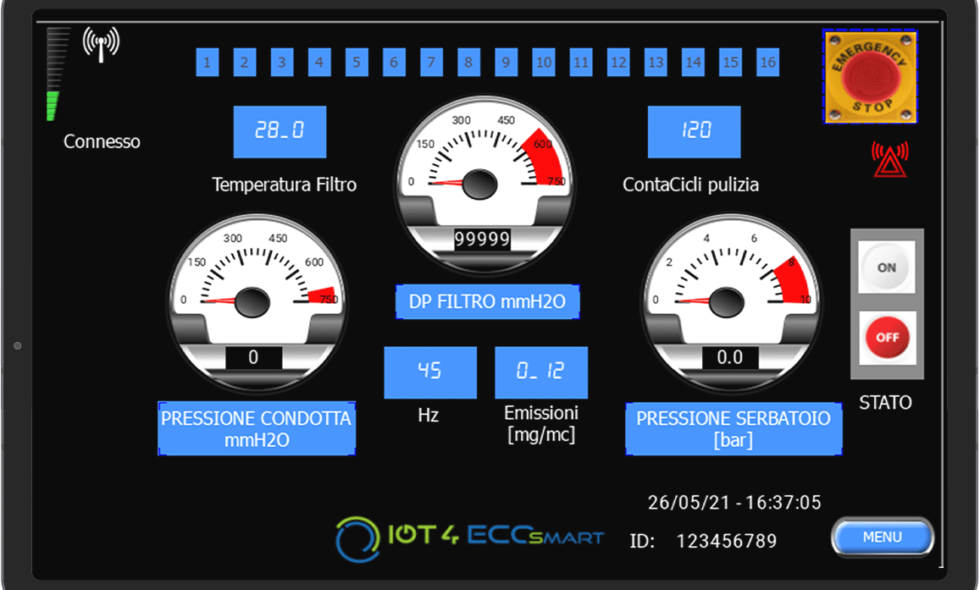

Cockpit

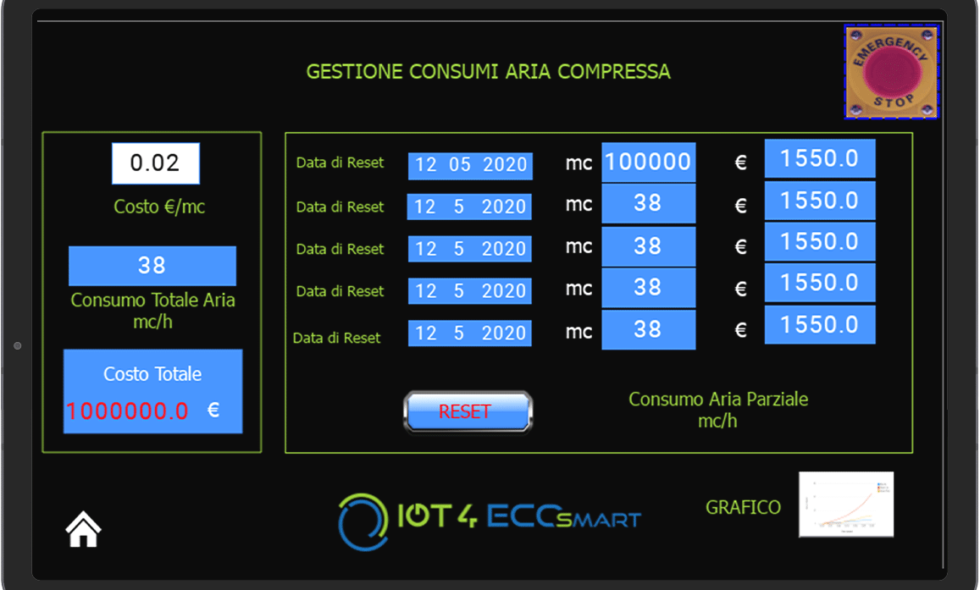

The main screen shown here allows you to have the main operating parameters of the filter under control, such as the pressure in the suction duct or the Δp of the filter. The latter is very important for the proper functioning of the system. Furthermore, it is possible to monitor in real time the emissions into the atmosphere, the temperature of the filter, the number of cleaning cycles performed, the consumption of compressed air, etc.

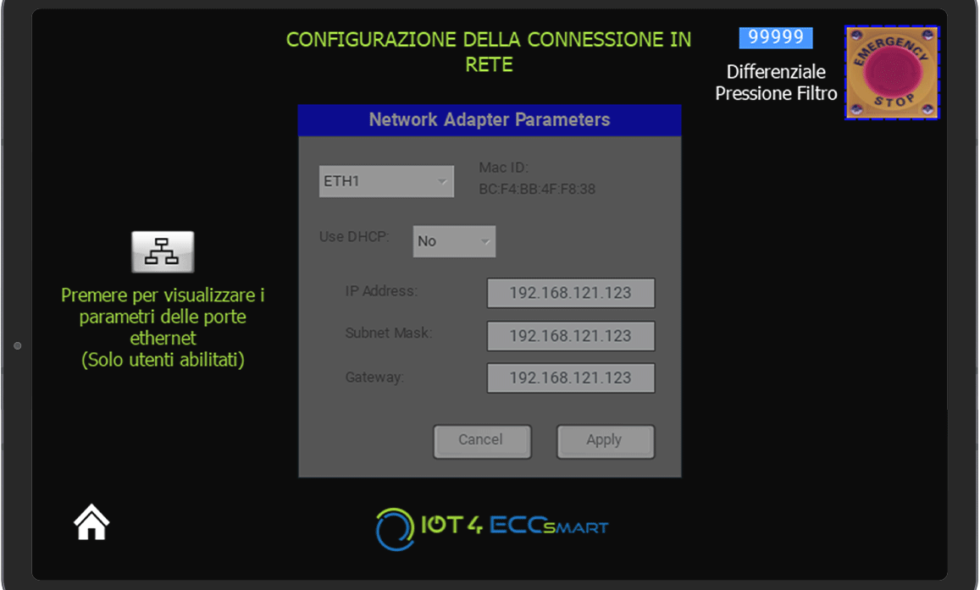

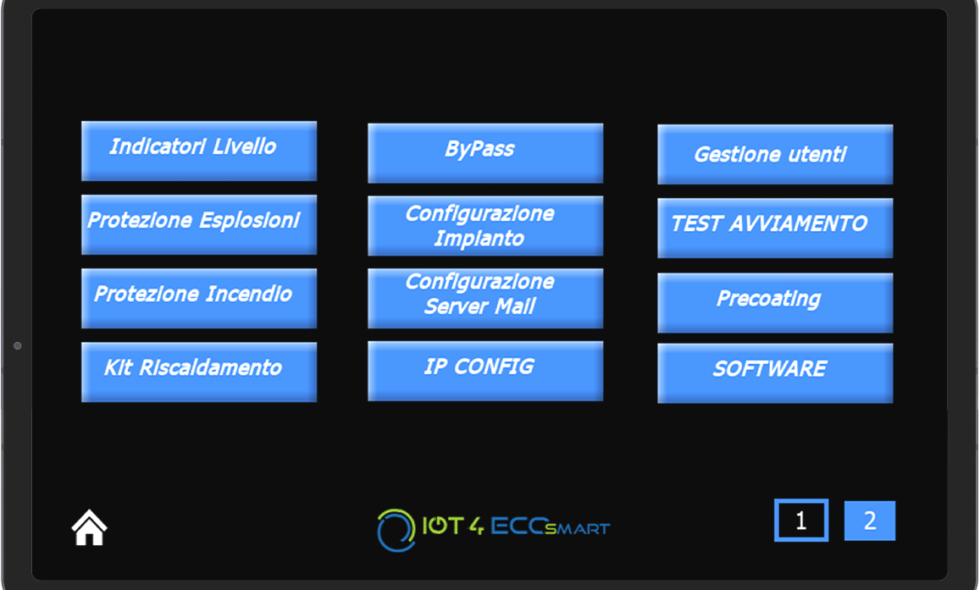

System configuration

What can we act on

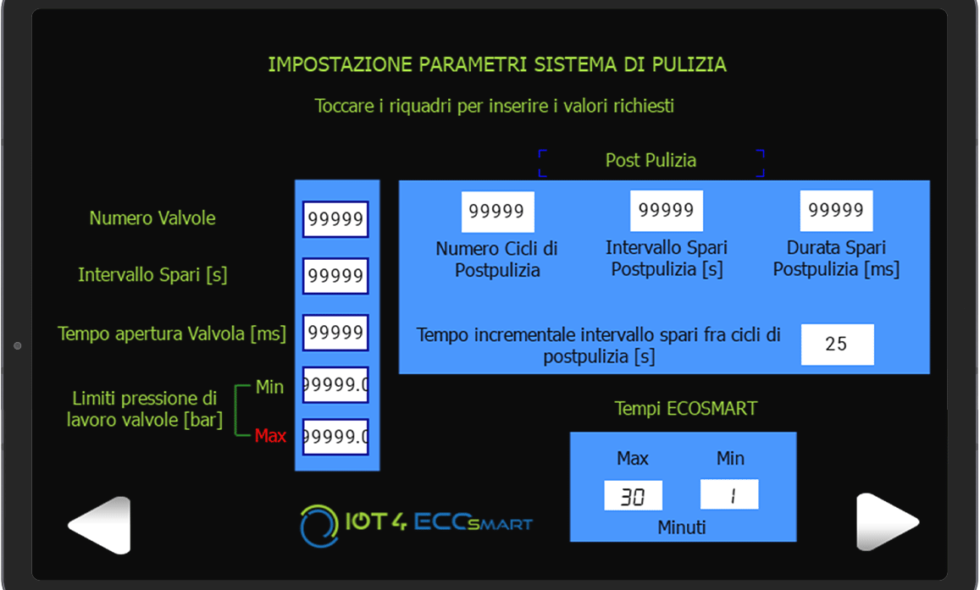

Cleaning parameters

Dedusting interval

Inverter parameters

suction motor adjustment

Pressure stabilizer

Flow meter

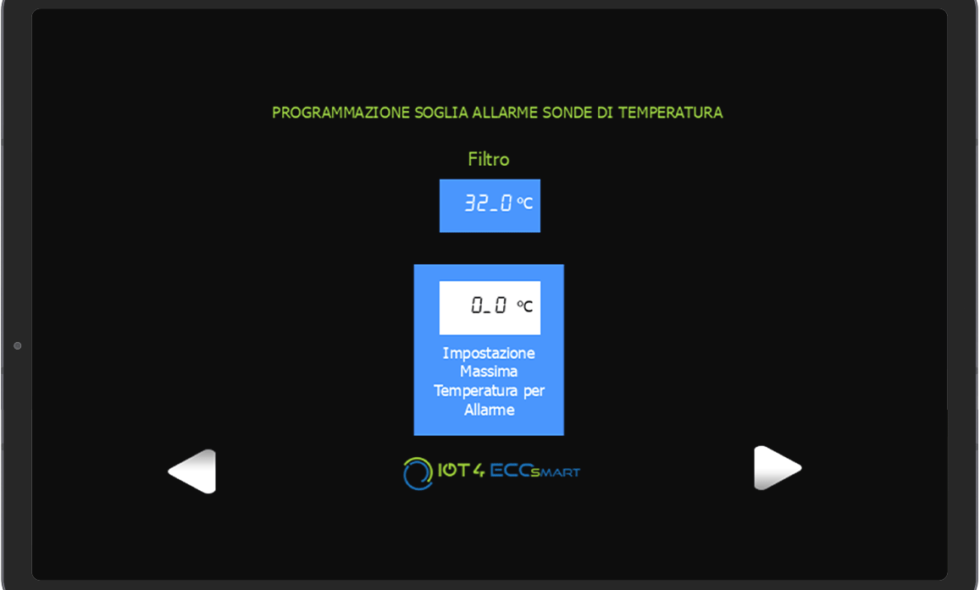

Tribo Probe Parameterization

Valve Shooting Sequence

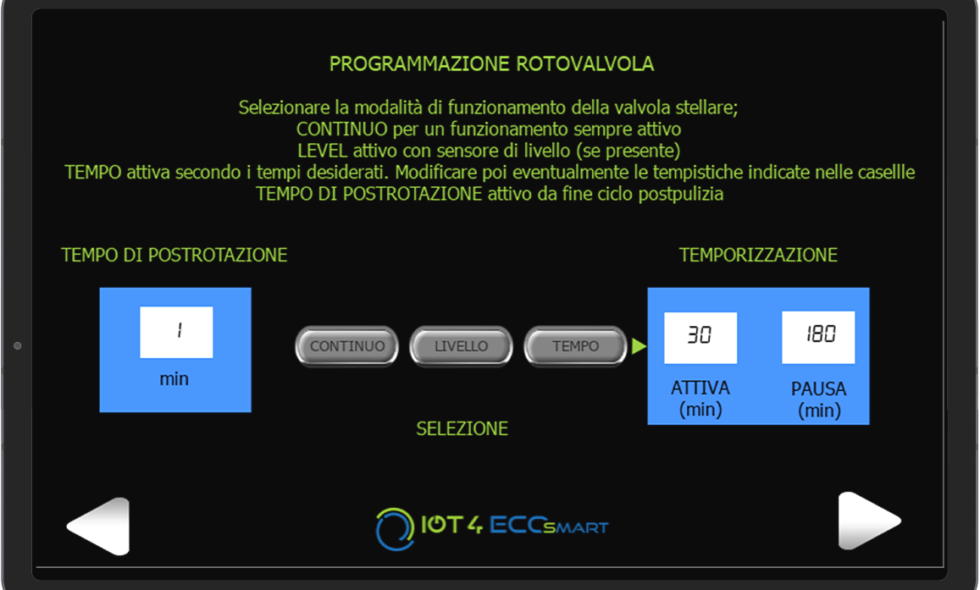

Rotary valve parameterization

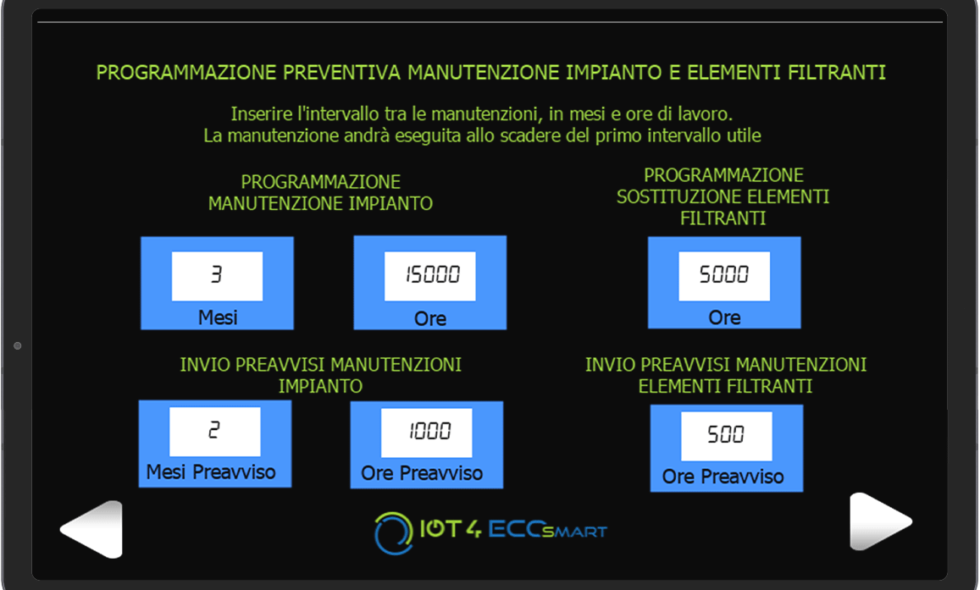

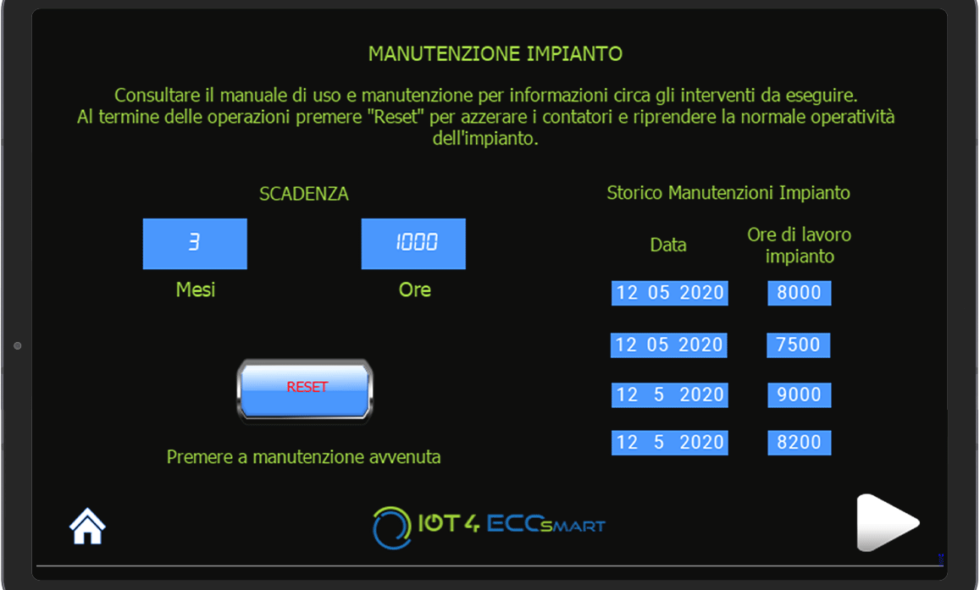

Scheduled maintenance

They represent a fundamental operation to keep the filtering system in efficiency. It is therefore important in order to subsequently be able to have notices informing about the expiration of the various maintenance.

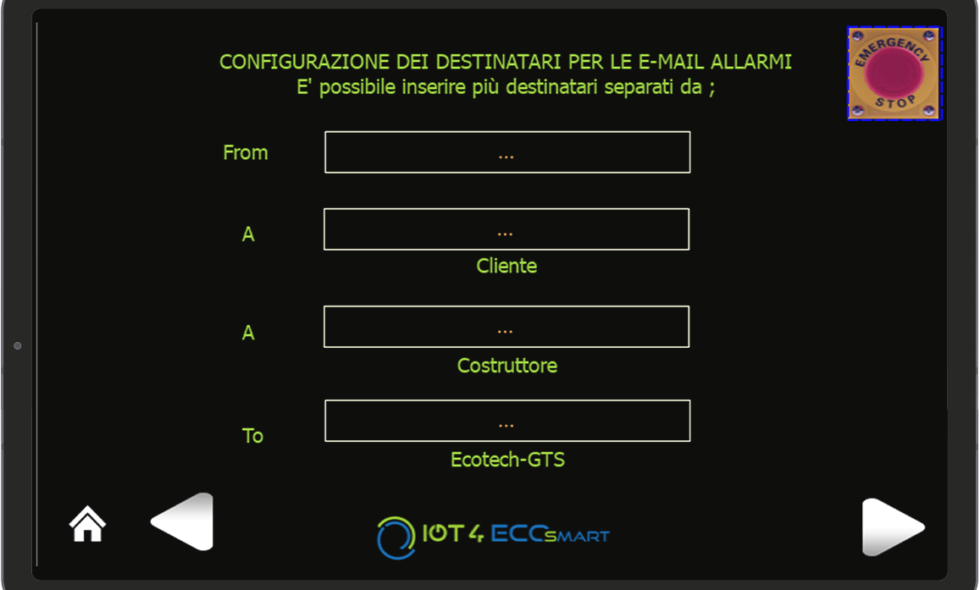

Alert by email

Spare parts

Data export

Air efficiency

Energy Efficiency

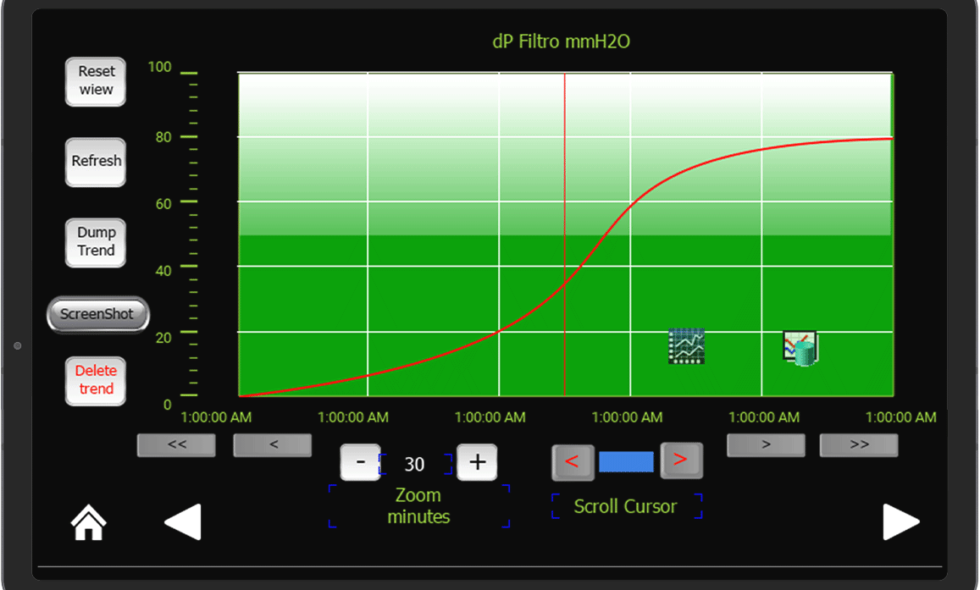

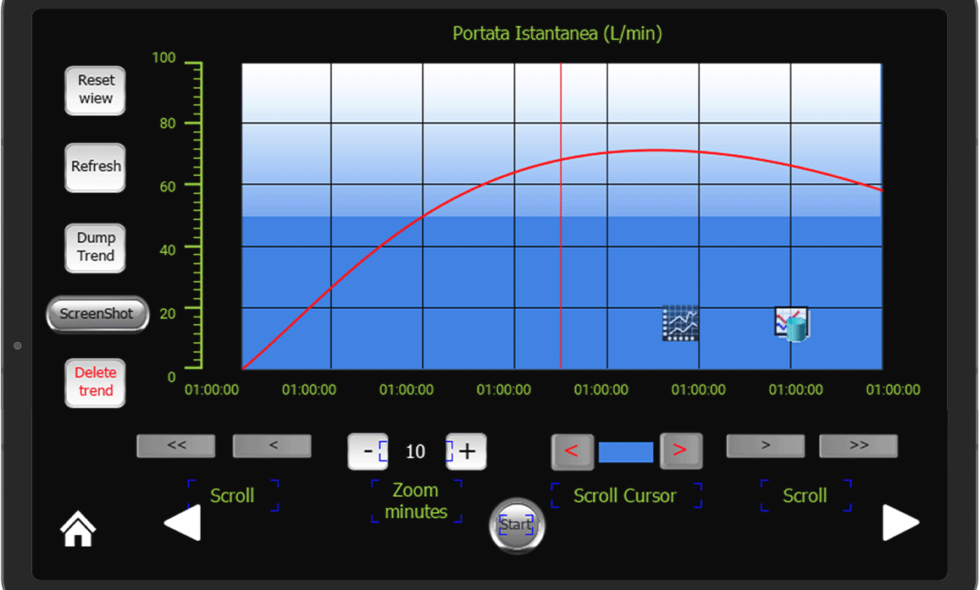

Drawing up of graphs

Data logger

One of the purposes of Industry 4.0 is also to provide a history of the progress of the various quantities relating to the plant or machine in question.

The IOT4-EcoSmart® system, consisting of the SMARTBOARD® + HMI Touch board, allows you to graph the values detected by probes or meters and display them on the screen or export the data in .csv format to consult or analyze them on a PC in table format.